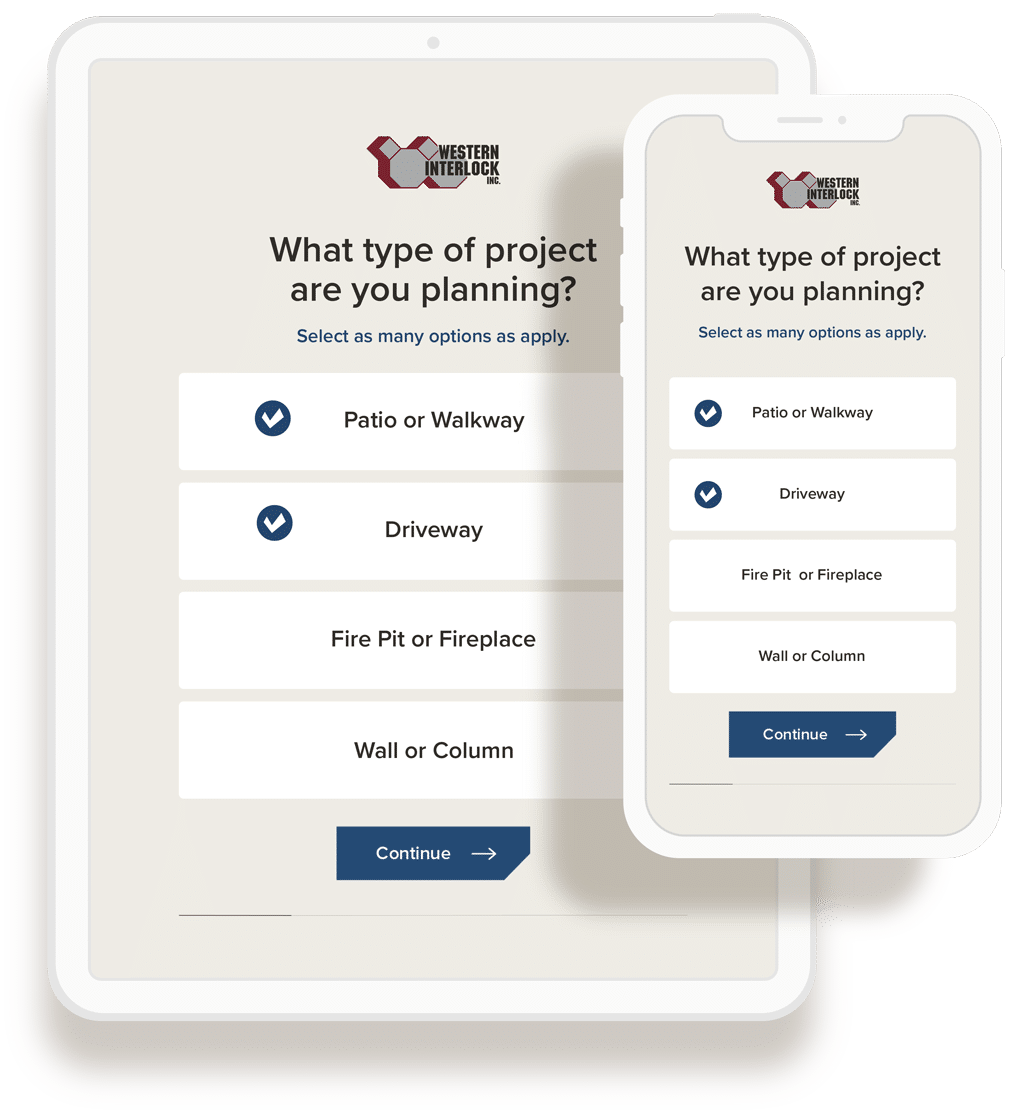

Get our FREE Project Planning Guide

"*" indicates required fields

If you set a stable base, you are 50% done with your project—it is one of the most important steps in laying pavers! To ensure your base is reliable, you must compact your gravel. In this blog post, you will learn how to best select a compactor for a reliable paver base.

Steel Tamper vs. Plate Compactor

Two tools are usually used for compacting gravel: a steel tamper and a plate compactor.

What is a steel tamper?

A steel tamper is made specifically for compacting elements such as gravel and asphalt.

It is a flat metal plate with a long handle on one end to make it easy for you to pack down the gravel you use for the paver base. You can easily find a steel tamper at your local Home Depot, Lowe’s, or another hardware store.

What is a plate compactor?

A plate compactor is an extra-large steel tamper that runs on a gas motor.

You can easily use a basic steel tamper if you are tackling a small paver project, but most paver projects, such as walkways, patios, or anything larger require a plate compactor.

What are the differences between a steel tamper and a plate compactor?

The main differences between a steel tamper and a plate compactor are size and expense.

A hand tamper is easily transported and can be bought for less than $50, or rented for $10 a day. A plate compactor, on the other hand, usually rents out from a hardware store at $85 a day and requires truck transportation and at least two people to lift it.

How to select a plate compactor

The rule of thumb for a plate compactor is that it can compact the same number of inches of gravel as it takes people to pick it up. So, if it takes two people to lift the plate compactor, it can probably compact two inches of gravel. If it takes six men to lift the compactor, it can probably compress six inches of gravel.

Light-duty plate compactor

For walkways and patios that will be used for a normal amount of pedestrian traffic, you should use a 14-inch plate compactor. Lay two to four gravel lifts (aka layers) to get to the proper amount.

Medium duty plate compactor

A 20-inch plate compactor should be used to compact the gravel where you will be laying pavers for walkways or patios with heavy pedestrian traffic. Lay four to six lifts of gravel under these pavers.

Heavy duty plate compactor

For driveways and parking spaces, use a 30-inch plate compactor. Vehicles require a stronger base, so plan to lay and compact six to eight lifts of gravel for your base.

Common questions

Do I need to rent a compactor?

You may wonder whether it is truly necessary to rent a power compactor. Isn’t it sufficient to hand-tamp a patio base?

It is possible to compact a patio base by hand, with a hand tamper. However, it will most likely take up a lot of time and be significantly more effort for you. It is slightly more expensive to rent a power compactor but is usually worth it for a large area.

Where can I get a compactor, and how much will it cost?

Plate compactors can be easily rented from a Home Depot or Lowe’s near you, or from your local hardware store. It usually costs around $85 per day or $340 per week for a 14-inch plate compactor.

Learn how to DIY

Laying pavers doesn’t have to be complicated. Learn how to DIY your patio or walkway with our DIY training videos.

Get our FREE Project Planning Guide

Tell us where to send it and we’ll email the backyard planning guide to you right away!

"*" indicates required fields