Milana™ Moderna

A larger format driveway paver offering a sleek, contemporary vibe. For this new paver, we've taken the module of our Alpine Stone and added the smooth surface and bevel from our popular Leiden Collection.

SERVING THE PACIFIC NORTHWEST

Your driveway is more than just a path to your home; it’s a statement of durability, design, and craftsmanship. At Western Interlock, we understand that a driveway should withstand the test of time, resist the elements, and enhance your home’s curb appeal. That’s why our driveway pavers are engineered for longevity, aesthetic versatility, and ease of maintenance.

At Western Interlock, we don’t just make pavers. We engineer solutions meant to last for decades. Each one of our stones reflects our commitment to craftsmanship, performance, and enduring beauty. Whether you're dealing with the freeze-thaw cycles of the Pacific Northwest or the wear and tear of daily use, our driveway pavers hold strong, resist shifting, and maintain their elegant finish year after year.

Unlike traditional poured concrete, which is prone to cracking and difficult repairs, our interlocking concrete pavers are designed to flex with the earth’s movements. This flexibility prevents unsightly cracks and ensures a stable surface for years to come. Each paver is manufactured to exceed 8,000 psi in compressive strength, making them suitable for both residential and commercial driveways.

Selecting the right paver depends on your specific needs, including load requirements, aesthetic preferences, and maintenance considerations. Some of our top recommendations for driveways include:

For permeable options, consider:

Creating a driveway with our pavers involves several key steps:

Installing driveway pavers is a manageable DIY project with the right tools and preparation. Here’s a step-by-step guide:

Regular maintenance keeps your driveway looking its best. Here are some effective cleaning methods:

Sealing your pavers enhances their appearance and protects them from stains and weathering. Here’s how to do it:

Extending your driveway with pavers is a practical way to increase parking space or enhance functionality. Here’s how to approach the project:

Whether you’re creating more room for guests, adding a turnaround space, or making room for an RV, extending your driveway with Western Interlock pavers gives you a high-performance surface that looks beautiful and lasts for decades.

When planning a new driveway, many homeowners consider asphalt or poured concrete. While those options may seem convenient, pavers offer superior long-term performance, aesthetics, and ease of repair.

Here’s why pavers are a better investment:

Over time, the value of a paver driveway becomes clear, not just in durability, but in curb appeal and reduced maintenance costs.

Living in the Pacific Northwest means dealing with a range of weather conditions from heavy rains to freeze-thaw cycles. Our pavers are crafted with low water absorption rates to resist moisture penetration, reducing the risk of damage from freezing and thawing. This design consideration ensures that your driveway remains intact and visually appealing, regardless of the season.

We offer a diverse selection of paver styles, colors, and patterns to complement any architectural design. Whether you prefer the classic look of cobblestone or a sleek, modern finish, our pavers can be arranged in various patterns, such as herringbone or running bond, to achieve your desired aesthetic.

For environmentally conscious homeowners, we provide permeable paver options that allow water to pass through the joints, reducing runoff and promoting natural groundwater recharge. These options not only support sustainable landscaping practices but also help manage stormwater effectively.

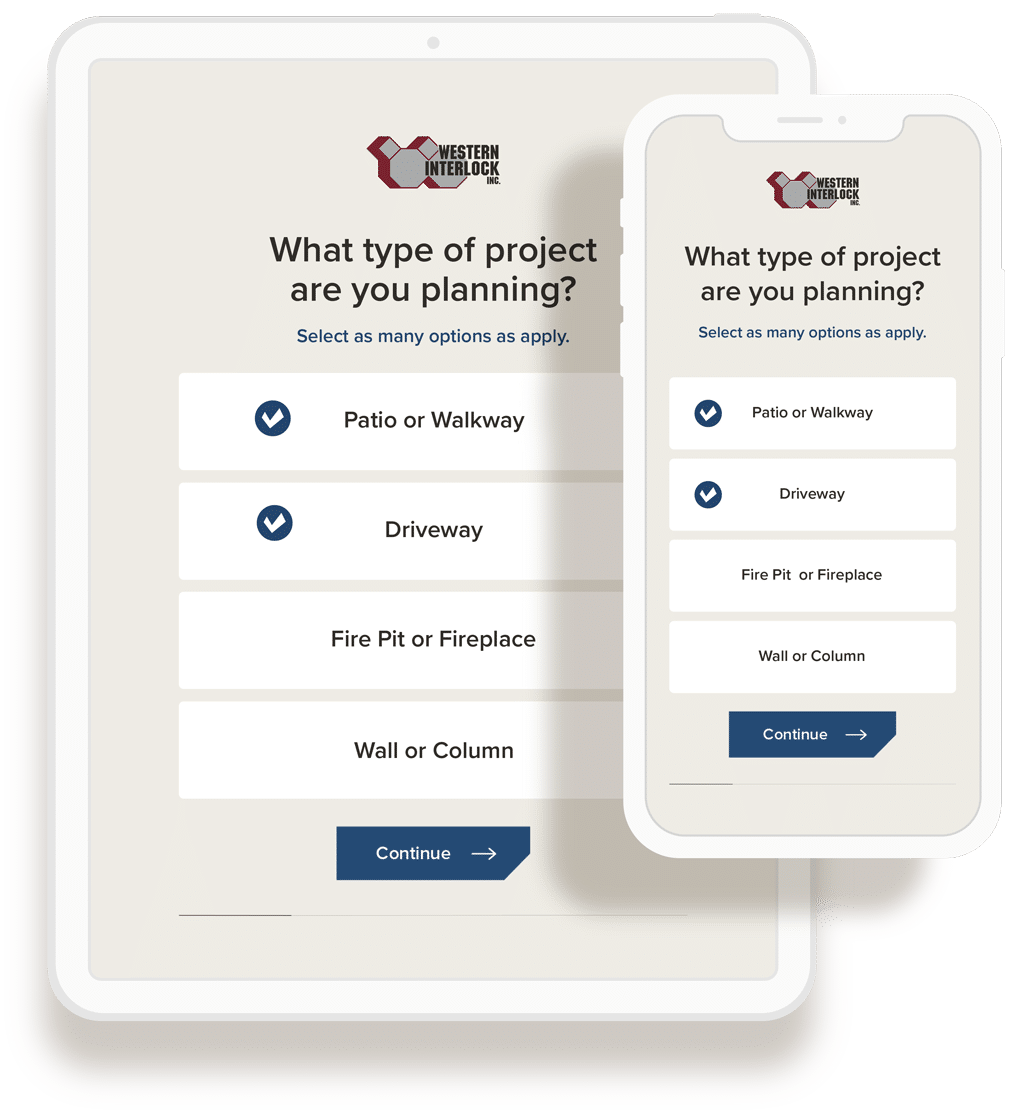

Choosing a paver can sure feel overwhelming. You have to consider size, style, thickness, color, and more. That’s why we made a short and simple quiz that asks a few questions about what you’re looking for and, at the end, provides a recommendation, or two, you can start with.

Learn More