How to Build a Raised Paver Patio

Building a raised paver patio is an excellent option for homeowners who want to expand or raise their outdoor entertainment area and create a cozy, relaxing spot. In this blog […]

Paving stones create a beautiful atmosphere just about anywhere. They are a stunning, low maintenance alternative to slab patios, concrete walkways, and more. But when you think about starting a hardscape project or trying to install pavers yourself, it can feel intimidating.

Before installing pavers, get clear on what hardscape is and what it’s used for. Additionally, understand the common mistakes to avoid and avoid them whenever possible. In this article, we share both, breaking down the 10-steps to properly install pavers.

To properly install pavers, you’ll need a few tools and materials. Here’s the short list of what we use. You can pick up any of these items at one of our Oregon or Washington sales offices, or your local hardware store.

Tools:

Materials:

The first step to installing pavers is to create a design that works for the hardscape’s location. Make sure to measure the area, calculate the square footage, then draw a print of the project.

Here at Western Interlock, we’re on a mission to take the hard out of hardscaping.

Decide which pattern of many patterns makes the most sense for your project and personal taste. Now, choose a color scheme that matches the surroundings. Depending on your hardscape, choose an accompanying border stone and layout.

Use white marking paint to create an outline of the hardscape on the ground. Increase the perimeter of the paint outline by 6” on all sides to account for the space needed for the edge restraint.

If you are laying a circular patio, place a stake in the center of the designated area. Tie a string to the stake that is 6″ longer than the radius of your patio. Use that string as a guide and spray a circle outline.

Next, at the corner of your project, create a 90° triangle using a stake and string and the 3-4-5 method. This square corner will be used as a guide to lay your pavers straight.

If you have a structure next to your patio, make sure each 90° corner is set to square. This will ensure that your paving stones will lay straight.

To allow proper water runoff, your project needs to slope away from any structures. Use a level (line or laser), to establish a finished grade slope of at least ⅛” per linear foot.

Place a stake on one side of the layout and another directly across from the first stake. Tie a string on both stakes and use a level to make sure it is perfectly flat. If you have a structure, make the string line even with the base of the structure. For every foot of line, adjust the line ⅛” down on the stake furthest from any building. The line is now your final grade for the project.

Many hardscape DIYers think that you can lay paving stones on dirt. No way! You need to establish a structurally sound base for them to settle into. To lay that base, you first need to excavate to remove dirt and debris.

Excavate the marked out area 7″ below finished grade. This depth allows for 4″ of the base material, 1″ of bedding sand, and 2″ for the stones.

Pro Tip: Most stones are 2⅜”, but after the pavers are compacted, it usually pushes them ⅜” into the base and bedding layers.

Most stones are 2⅜”, but after the pavers are compacted, it usually pushes them ⅜” into the base and bedding layers.

The next step is to set the base for the hardscape. First, lay geotextile over the dirt to act as a barrier between the soil and the gravel.

Place ¾” minus gravel in the excavated area and compact it to 3″ below where the patio will lay. The base needs to be smooth and even, as any surface imperfections will be evident in the final product.

Run a flat board over the gravel to even out any rises or dips. Any rises or dips more than ⅛” will be noticeable in the final product. In other words, you’ll feel that your pavers are uneven.

Place 1″ screed rails on the gravel. Grab a screed board and adjust the rails to be closer together than the distance of the board so that your board can slide smoothly over the sand.

Pour a layer of concrete sand thick enough to level out at 1″ in depth. Use a screed board to pull the sand between the rails to a uniform depth.

Starting at the 90° string and stake corner, lay the first paver, making sure the edges are running parallel to the strings. Now use the click-drop method to lay the remaining stones. First, click the stone tight against its neighbors, then drop it into place. Do not scoot pavers on the sand bed.

When you come to an edge, you may need to miter a corner. To miter a corner, cut the corner stones at the required angle to create a flush corner. If you have never cut a paving stone check out our article and video: 6 Ways to Cut a Paving Stone.

If your hardscape design includes a border, lay the border following the same click and drop method.

Next, install edge restraint around the border. We recommend using Snap Edge. Scrape any sand away from the border, exposing the gravel base. Place the edge restraint on the gravel as tight against the border as possible. Nail in every third hole using 10″ spikes. Make sure to cover the snap edge with sand or dirt to reduce the chance of warping.

To finish the project, depending on the type of stone, compact the pavers. Sweep the hardscape’s joints full of polymeric sand and then compact again. Sweep off any remaining sand, wet the joints, pull up some chairs, and enjoy your complete patio.

Here at Western Interlock, we’re on a mission to take the hard out of hardscaping. That’s why we publish DIY tips, tricks, and step-by-step tutorials at DIYwithWI.com.

If you have any questions, you can visit our Paving Stone Display at our Manufacturing Facility in Rickreall, OR. Or, give us a call to our team of hardscape experts at 503-623-9084.

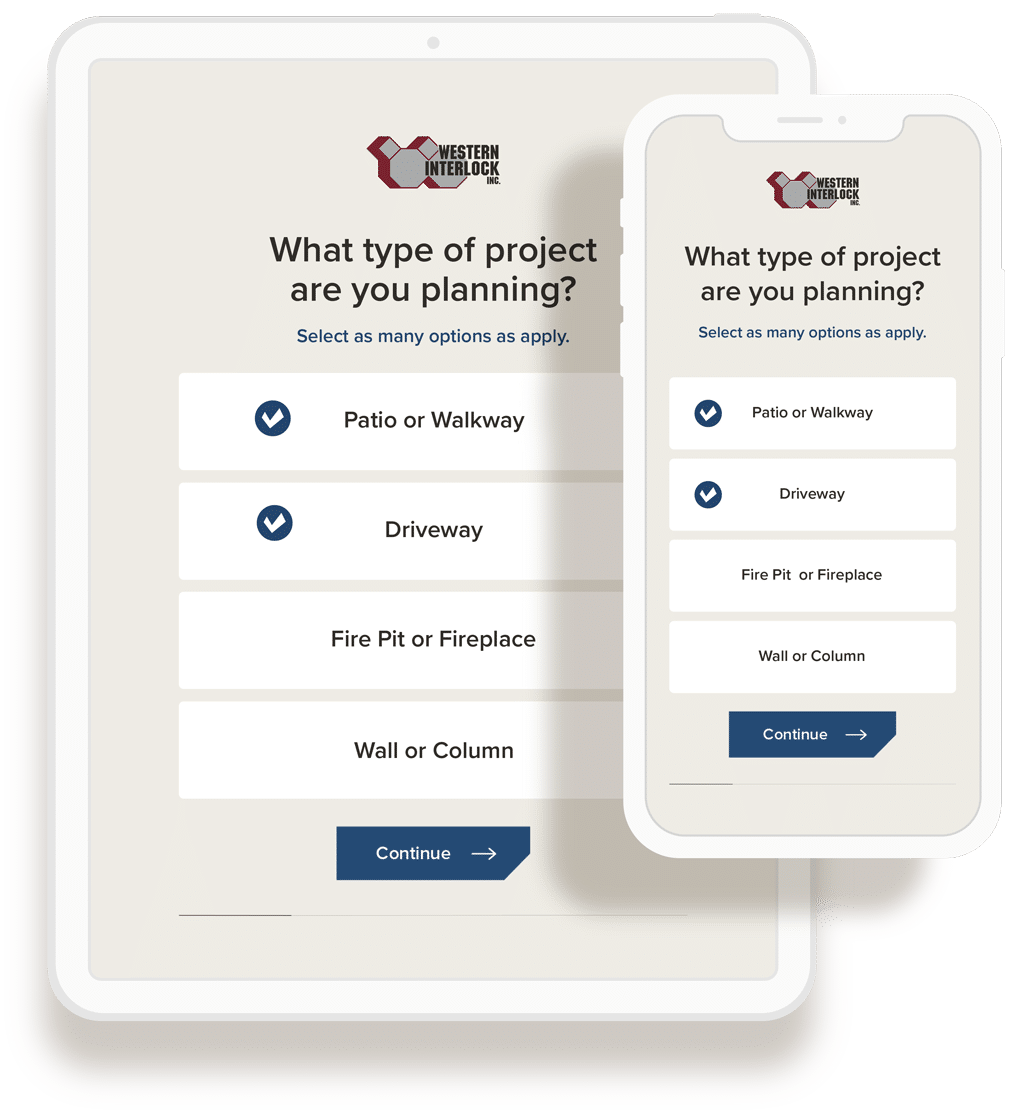

Choosing a paver can sure feel overwhelming. You have to consider size, style, thickness, color, and more. That’s why we made a short and simple quiz that asks a few questions about what you’re looking for and, at the end, provides a recommendation, or two, you can start with.

Learn More